Heated glass technology in one form or another has been used in ships and aircraft for many years to prevent the windows frosting over. By heating the low emissivity surface of a glass unit, we can implement this into modern double or triple-glazing units – bringing anti-freeze properties to both the commercial and the residential glazing sectors.

By orienting NUCLR with the heated pane facing out of a building, we can ensure that no snow or ice forms on the glass surface.

This can be particularly useful in very cold climates where snow and ice are common issues. NUCLR not only ensures maximum clarity, but also that no excess load is applied to the glass. For example, on rooflights and canopies.

Any control system for this configuration would be based upon an external temperature sensor, switching the heated glass on when air temperature falls below a given value and switching it off when above a certain value. 4 °C and 6°C, for example.

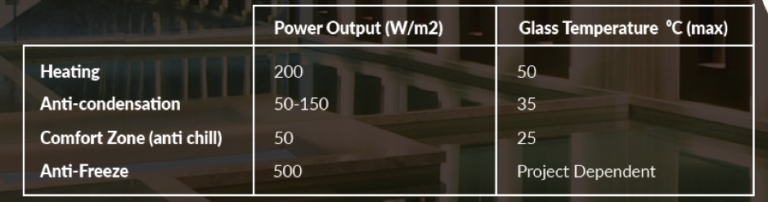

As seen in the table below, it is recommended that a power output of at least 500W/m2 be used for anti-freeze, so the glass can heat up rapidly in cold climates. But as NUCLR is a bespoke product, this can be tailored to specific requirements.