Low Emissivity Coatings

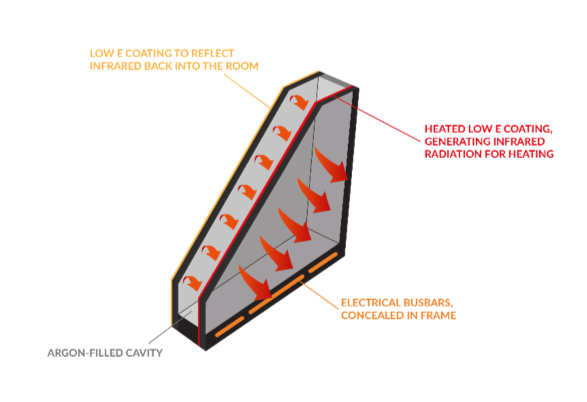

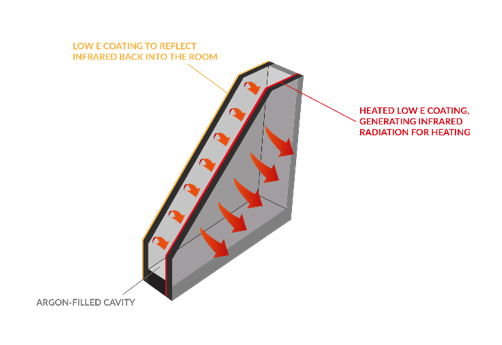

A Low emissivity coating (low-e), is a coating applied to one surface or a glass pane that alters the thermal properties and the light transmission of the glass. This is used to help control the solar gain from the glazing, and to increase the thermal efficiency of the building by reducing the windows U-value. A low-e coating is made of various metallic oxides, and so can be used to conduct electricity. This surface can either be built inside of an insulating glass unit or laminated inside a single pane of NUCLR.

Heating

When electricity is passed over the surface of glass with a low-e coating, the glass emits radiant heat.

Infrared radiation is emitted into the space, as well as warming the surface of the glass as per the diagram. This is felt on the skin much like the sun on a warm day. It warms surfaces, rather than the atmosphere surrounding, meaning fewer cool spots and drafts are caused by moving air currents around a room.

Power

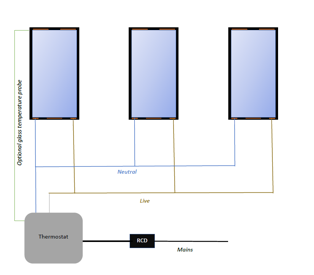

NUCLR heated glass is designed to operate from a 230V mains input. This is attached to the busbars via a thermostat and safety device as per the wiring diagram.

We control the power output from each NUCLR panel by altering the electrical properties of the low-e coating. With some careful mathematics, the surface of the coating is altered with a high-powered laser to achieve our desired power level for each application. This editing comes in the form of either near-invisible laser lines, or a hexagonal lattice.

NUCLR is a bespoke solution, therefore each design is unique and will be created to best fit the project requirements.

Concealed Design

Wires enter the unit through the secondary sealant and are soldered to the busbars on the internal glass surface. These are hidden inside the sealant of the unit, which in turn is then hidden by the chosen framing system of the designer. Cables are run through the frame, away to the thermostat and power supply.

Power Levels and Applications

Heated glass requires different properties, depending on the desired application of the glass. For example, less power is required to prevent condensation, than to warm a room.

NUCLR power levels:

|

Application |

Power Output (Wm-2) |

Glass Temperature °C (Approximate) |

|

|

|

|

|

Anti-Chill (comfort zone) |

50-100 |

25

|

|

Anti-Condensation

|

50-200 |

30 |

|

Space Heating

|

200-500 |

50 |

|

Anti-freeze

|

500 + |

Project Dependent |

NUCLR

· Maximum Size 3m x 2.4m standard, larger may be available on request

· Heat Soak Tested

· 230V mains supply via thermostatic control or simple switch

· Double or triple IGU

· Single laminate panes

· Installs into most glazing systems

· 1.0 U value in DGU

· Double low-e units for maximum thermal efficiency