NUCLR Heated Glass

Experience Rapid, Energy-Efficient Heating with NUCLR Glass for Modern Residential and Commercial Spaces.

NUCLR glass offers rapid, energy-efficient heating using advanced short wave radio technology. Perfect for modern residential and commercial spaces, it provides immediate warmth while reducing energy consumption, making it an eco-friendly and cost-effective heating solution.

NUCLR - how it works

EXPLORE FEATURES

Discover the benefits of NUCLR glass heating technology.

Main Room Heating

NUCLR can be configured so that it is the sole method of heating a space, producing a sleek and stylish finish whilst doing away with the need for bulky radiators or expensive underfloor heating.

One of the many challenges when designing a new space is how it is heated. Be this an extension to an existing dwelling, a new build, or a refurbishment of an older building, heating a space provides significant M&E challenges that must be overcome on each project.

The use of electricity as a heat source removes many of these challenges. There is reduced requirement for hidden pipework within walls and ceilings, and therefore a simpler design can be implemented.

Using NUCLR as the primary heating method for a space will not only reduce a project’s dependence of M&E design and limitations, but also incorporate heating without the use of bulky radiators or electric heaters.

NUCLR’s infrared heating projects warmth across a room creating a comfortable, uniform environment. Not only this, using NUCLR as a primary heat source also carries the added benefits found with an anti-condensation and anti-chill installation.

When heating a space, it is important to calculate how much power is required. When specifying heated glass to a project, the following is recommended:

- An area of glazing equivalent to at least 20% of the floor space for a standard height room (up to 3 metres)

- A calculation based on 80W/m2 of floor space being necessary to heat the space*

Due to the high efficiency of infrared heating, 80W/m2 of power is a guideline, rather than 100W/m2 with other forms of heating. Using these guides, we can propose appropriate heating solutions for most projects, ensuring maximum efficiency and comfort within the space.

Anti Chill

NUCLR can be used in conjunction with conventional heating systems. When warmed to room temperature, NUCLR eliminates the cold feeling around large installations of glazing. Perfect for keeping the chill out of any glass boxes, conservatories, or bi-folding door installations, as well as reducing drafts around a room.

Even with modern advances in the glazing industry, large installations of glass are relatively poor thermal insulators when compared to insulated walls.

As heat escapes through the glass at a faster rate than through any nearby walls, an area of lower temperature can be felt in the air nearby. This can be particularly problematic where comfort in all areas of a space are required.

Most notably in restaurants, but other use-cases include: Conservatories, Kitchen Extensions (bi folding / sliding doors), rooflights.

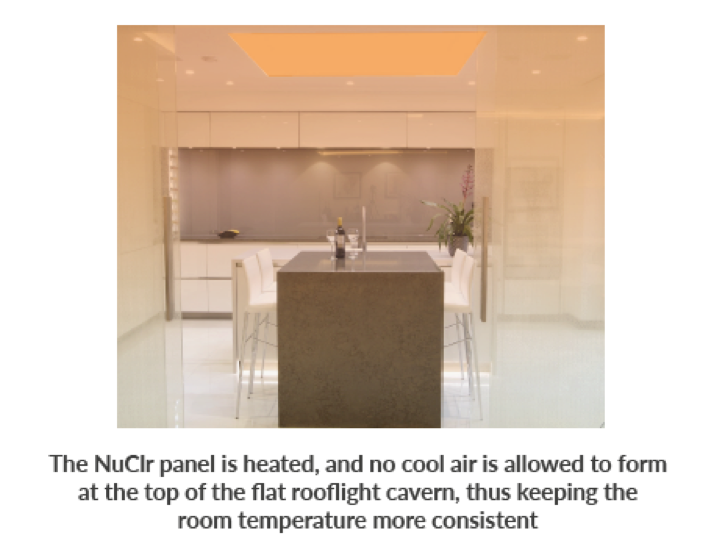

Rooflights are particularly susceptible to developing large areas of cooler air beneath them. When this air becomes cool enough, it sinks through the surrounding warmer air, creating the “cold drop” effect as illustrated below. This can make an environment less comfortable, potentially making people turn heating up a few degrees to compensate. Eliminating chills with heated glass is done with minimal power usage. Just 50W/m2 is enough to raise the glass temperature enough to prevent heat being drawn from the surrounding air, ensuring the most comfortable environment possible.

Anti Condensation

Where clarity is desirable in regular or high humidity environments, NUCLR will eliminate condensation build up – making it the ideal product for installations such as luxury spas, heated pools, kitchens and bathrooms.

Condensation has long been an issue on windows and doors. Not only can it be time consuming to wipe away, but it also obscures views. Particularly in the morning after a chilly night. Condensation forms on glass and other cold surfaces due to two factors:

- Excess humidity in the air

- Temperature difference between a surface and the surrounding humid air

Windows, doors and glass partitions are particularly susceptible to condensation as they are regularly installed in environments that meet the above criteria. The temperature at which a surface must be to allow condensation to form, is known as its Dew Point. This is calculated by several factors, including the temperature and relative humidity of the surrounding air.

If glass in a window, door, or partition falls below the dew point, condensation will begin to form on either the inside pane or the outside pane of glass, depending on the conditions and time of year.

NUCLR heated glass can ensure that the surface does not drop below the dew point – preventing the build up of condensation entirely. Low power is required to use NUCLR for anti-condensation, as little as 50-150W/m2 of glazing is sufficient to heat the glass to anywhere between 20°C – 35°C. NUCLR for anti-condensation is often used in swimming pool areas, such as our West Hampstead Case Study: Recently, we have also used NUCLR to prevent condensation on an enclosure at one of the UK’s leading Zoos. We hope to have a case study completed soon.

Ice and Snow Defrosting

NUCLR can be configured in a way to not only defrost snow and ice, but prevent its build-up entirely. If you have a project in a cold climate that’s subject to freezing, NUCLR will ensure that clarity is maintained all year round.

Heated glass technology in one form or another has been used in ships and aircraft for many years to prevent the windows frosting over. By heating the low emissivity surface of a glass unit, we can implement this into modern double or triple-glazing units – bringing anti-freeze properties to both the commercial and the residential glazing sectors.

By orienting NUCLR with the heated pane facing out of a building, we can ensure that no snow or ice forms on the glass surface.

This can be particularly useful in very cold climates where snow and ice are common issues. NUCLR not only ensures maximum clarity, but also that no excess load is applied to the glass. For example, on rooflights and canopies.

Any control system for this configuration would be based upon an external temperature sensor, switching the heated glass on when air temperature falls below a given value and switching it off when above a certain value. 4 °C and 6°C, for example.

As seen in the table below, it is recommended that a power output of at least 500W/m2 be used for anti-freeze, so the glass can heat up rapidly in cold climates. But as NUCLR is a bespoke product, this can be tailored to specific requirements.

TECHNOLOGY

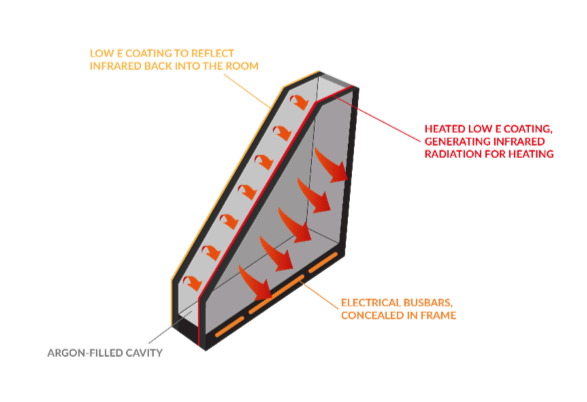

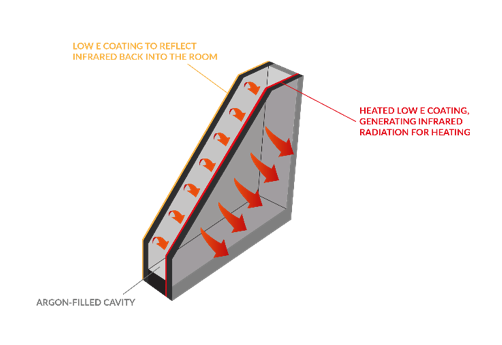

Low Emissivity Coatings

A Low emissivity coating (low-e), is a coating applied to one surface or a glass pane that alters the thermal properties and the light transmission of the glass.

This is used to help control the solar gain from the glazing, and to increase the thermal efficiency of the building by reducing the windows U-value. A low-e coating is made of various metallic oxides, and so can be used to conduct electricity. This surface can either be built inside of an insulating glass unit or laminated inside a single pane of NUCLR.

POWER

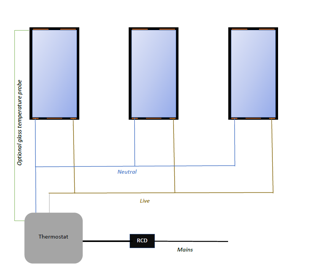

NUCLR heated glass is designed to operate from a 230V mains input. This is attached to the busbars via a thermostat and safety device as per the wiring diagram.

We control the power output from each NUCLR panel by altering the electrical properties of the low-e coating. With some careful mathematics, the surface of the coating is altered with a high-powered laser to achieve our desired power level for each application. This editing comes in the form of either near-invisible laser lines, or a hexagonal lattice.

NUCLR is a bespoke solution, therefore each design is unique and will be created to best fit the project requirements.

CONCEALED DESIGN

Wires enter the unit through the secondary sealant and are soldered to the busbars on the internal glass surface.

These are hidden inside the sealant of the unit, which in turn is then hidden by the chosen framing system of the designer. Cables are run through the frame, away to the thermostat and power supply.

NUCLR POWER LEVELS

Power Levels and Applications

Heated glass requires different properties, depending on the desired application of the glass. For example, less power is required to prevent condensation, than to warm a room.

| Application | Power Output (Wm-2) | Glass Temperature °C (Approximate) |

| Anti-Chill (comfort zone) | 50-100 | 25

|

| Anti-Condensation

|

50-200 | 30 |

| Space Heating

|

200-500 | 50 |

| Anti-freeze

|

500 + | Project Dependent |

TESTIMONIAL

What They’re Saying

FAQ

Can I replace just double glazing in my current PVC windows?

Yes. C.U.in will provide unrivalled insulation in your existing windows. This is an economical solution and even more environmentally friendly way to achieve excellent insulation when windows in good condition. Follow the link for find an installer and one of our approved installers will be able to quote for replacing just the glass instead of the whole window.

What are U-values?

U-values are the measure of heat loss through a material. The lower the number, the less heat loss, therefore better thermal insulation.

What is low E glass?

Low e, meaning low emissivity is an invisible coating applied to one surface of the glass. Low e glass helps to reflect the heat we produce in our homes through central heating back into the room keeping it warmer.

Why should we choose C.U.in over generic double glazing?

C.U.in is more thermally insulating, has better sound insulating properties and better for the environment than double glazing. C.U.in will also reduce your energy bills.

How cost effective is C.U.in?

C.U.in can reduce your energy bills by over £300 per year. The actual amount will vary depending on several factors such as area of glazing and existing type of glazing.

Can I replace any of my window units with C.U.in?

Yes C.U.in can be replaced into virtually any window that already has double or triple glazing installed.

How much does C.U.in cost?

The cost of C.U.in depends on if you are having new windows or just replacing the glazing in your existing windows. If you are looking for C.U.in in your new windows, please complete the new window enquiry form speak on our home page and we can direct you to a selection of our C.U.in certified window specialist or you can simply ask for C.U.in by Crystal Units from your windows installer if you have already chosen your windows. If you a looking to replace the glazing in your existing windows, please complete the Replacing Glazing enquiry form on our home page and we can provide you with a cost.

Can I replace my current triple glazing units in my current windows?

Yes C.U.in can be replaced into virtually any window that already has double or triple glazing installed.

Does C.U.in come in a maximum size?

The maximum size for C.U.in is 3000mm x 6000mm